Gone forever: SRP detonates last blast at NGS

Navajo Times | Krista Allen

Large excavators operated by Salt River Project’s demolition contractor, Independence Excavating of Cleveland, Ohio, tear down the turbine block building at the Navajo Generating Station in LeChee, Ariz. Demolition of the power block began the week of June 15 with three consecutive days of explosions by explosive contractor Demtech of Saxonburg, Penn.

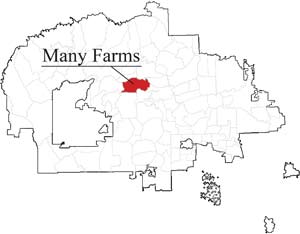

LICHÍI’II Ariz.

What people could see of the Navajo Generating Station from State Route 98, which links Shonto and Page, is gone forever.

Blasted to piles of rubble were the Three Sisters (units 1, 2, and 3), the concrete-and-rebar pillars and pedestals, the boilers, scrubber equipment, electrostatic precipitators, brine concentrators, coal yard, and the power block.

For many NGS employees, also blasted away were jobs and a 45-year history was erased.

Salt River Project’s explosive subcontractor – Demtech of Saxonburg, Pennsylvania – conducted three consecutive days of implosions to bring down the power block two weeks ago.

The implosions took place June 15 to 17 and demolished NGS’s footprint, the 40-foot-tall concrete-and-rebar pillars and pedestals that supported NGS’s power-making turbines.

Each unit had a turbine and each had 14 pillars supporting its respective three pedestals, said George Hardeen, spokesman for NGS.

Demtech explosive crews used 2,800 pounds of explosives per unit.

Final explosion

Gary Barras, SRP’s director of major projects and the NGS Decommissioning and Demolition Project supervisor, was given the honor of detonating the final explosion of the Unit 3 pedestals on June 17.

“It’s a mixed feeling,” Barras said. “It’s a major milestone for our project goals.”

On the one hand, Barras said SRP, along with prime contractors and subcontractors, is working hard to properly turn the NGS site back over to the Navajo Nation following all obligations.

“On the other hand, it’s bittersweet,” Barras said. “Early in my career I got to work with some of the men who were instrumental in building this plant – guys like Trent Meacham (SRP’s assistant general manager for Power, Construction and Maintenance) and John Rich (SRP’s assistant general manager for Power Operations).”

Barras said he was also thinking of the countless men and women who designed, built, maintained, and operated the power plant for nearly five decades.

“I want to do this in honor of those guys and women and the work that they did,” he said. “I want to really pay tribute to those who cared about NGS through the years and say thank you to them.”

Barras estimates that most of the demolition work will be completed a year from now. But that doesn’t mean the project is over because there is still work to be done.

Barras said a contractor will come in this summer to begin earthwork.

“There are those numerous evaporation ponds, which of course are all empty now,” Hardeen explained. “Draining everything is the first process of decommissioning a power plant.”

The cost of decommissioning NGS is around $150 million, according to SRP. Based on initial studies, SRP officials estimate that more than 90% of the decommissioned plant will be salvageable.

Cincinnati-based Independence Excavating, NGS’s prime demolition contractor for the power block, began tearing down the turbine block building on June 18.

The building housed all three turbines and the control rooms where power was made, said Hardeen.

“The turbines were at the 40-foot level,” Hardeen said. “But the building went up much higher than that. The demolition of that is happening very fast because that is just steel girders; and metal sheeting on the outside did not need to be demolished with explosives (because) this is the kind of thing that big excavators can basically tear down.”

Hardeen describes the debris from the demolition as a “mountain range of twisted metal,” which needs to be processed or cut into manageable sizes so it can be loaded onto 18-wheeler trucks and transported to recycling facilities.

Zero-liquid discharge

NGS was a zero-liquid discharge facility, meaning that all water brought into the plant site was reclaimed and reused and there was no liquid water discharge from the plant site.

Any wastewater generated by plant operation activities was put into large evaporation ponds – as part of the system to capture and regulate wastewater flow – to accomplish zero discharge.

Those evaporation ponds are still on-site and awaiting disposal by a contractor specializing in that kind of work.

“The lease agreement with the Navajo Nation provides five years to get everything completed,” Hardeen said.

During this time, better known as “NGS retirement,” SRP must remove NGS and restore the surface of the site under the provisions of the extension lease between the Nation and SRP; Arizona Public Service; Tucson Electric; Nevada Power; and Los Angeles Department of Water and Power.

The NGS retirement period is the lease term that started on Dec. 23, 2019. It continues through Dec. 22, 2024.

The NGS site remediation period begins after that date, and it will continue through Dec. 22, 2054. But some site remediation may occur during the retirement period, according to the extension lease.

The NGS Decommissioning and Demolition Project took a brief pause last year because of the coronavirus. After a nearly four-month suspension, the project resumed in July 2020 with the demolition of the Unit 3 absorber pumphouse and the 10-story-high limestone preparation conveyor.

Barras said regardless of the work suspension from March 27 to July 26, 2020, the demolition contractors made up for lost time and the demolition phase is back on schedule.

“So far we’re really pleased with everything that’s happened,” Barras said. “We haven’t had any major issues with the (two) switchyards. We haven’t had any issues from a safety standpoint.”

All on-site electrical power was supplied by output from the three units except about 200 megawatt-hours a year from the 230-kilovolt switchyard that came from the hydropower generated at Dá’deest?’in Hótsaa or from Tódinéeshzhee’. It was used for emergency backup power to the units and the lake pump station.

The 500-kilovolt switchyard (Moenkopi Switchyard) was used to transmit the plant’s electrical output to NGS participants. It was controlled and operated by APS.

Monitoring for 35 years

SRP officials said the demolition work is right on schedule. But once the NGS site is reclaimed and reseeded, SRP will continue to monitor it for 33 more years, according to the 35-year extension lease term.

“That will be environmental monitoring because what we see will be gone with the exception of a few buildings that (have) been selected by the Navajo Nation,” Hardeen explained. “SRP will continue to do monitoring for any kind of change.”

The Navajo Nation retained assets including the Black Mesa and Lake Powell Railroad that goes to Peabody Western Coal Company’s twin silos in Klethla Valley near Kayenta Mine; the administration, maintenance, and warehouse facilities; and the lake pump station.

These buildings were constructed in the mid-1990s as part of the scrubber project and they are in excellent condition, said Hardeen.

Navajo Times | Krista Allen

This is the remains of the Black Mesa and Lake Powell Railroad near State Route 98 in LeChee, Ariz. The catenary line that powered the railroad was removed during the first phase of decommissioning. The 78-mile long railroad is now under the jurisdiction of the Navajo Nation.

President Jonathan Nez said plans for the retained assets are currently underway. The plans include developing the railroad into a waterline for agriculture and farming; transforming the warehouse into a tourism hub for businesses; and transforming the administration and maintenance facilities into an economic development opportunity.

“And the lake pump (station) for the waterline upon the railroad,” Nez told the Navajo Times, “and water for LeChee and surrounding communities (in Western Navajo). (This) may include the Western Navajo Pipeline.”

The assets are now the property of the Navajo Nation, according to the lease agreement, which states that the railroad and related facilities have a replacement value of about $120 million.

The lake pump station, its suction piping, discharge piping to the plant metering pit, electrical distribution lines from the switchyards have a value of about $41 million.

The NGS participants paid nearly $19 million to the Nation for cost savings associated with not decommissioning those facilities and paid $3.6 million to fund a solid waste disposal program.

The extension lease provides payments totaling about $110 million to the Nation. It allows continued access to the site for decommissioning, long-term monitoring, and ongoing operation of the transmission system.

The NGS participants will pay the Nation’s share of operations and maintenance costs at the station for 10 years, at a projected value of $5 million.

Final blasts

This month’s implosions are the final blasts at the NGS site after the plant went offline in November 2019, when SPR permanently shut down all three units.

NGS’s three, 775-foot smokestacks and 199-foot-high steel-frame Unit 3 electrostatic precipitator (that captured fly ash) were demolished on the morning of Dec. 18, 2020.

The three, reinforced concrete stacks were built in the mid-1990s to replace the three original NGS stacks as part of the NGS scrubber project to remove sulfur dioxide from NGS emissions.

“We removed the 220-foot original stacks in November (2020),” Hardeen said. “They also were once 775-feet tall. But when the new stacks went in, in the 1990s, they were reduced in size. And then we demolished the 775-foot stacks that people have come to know (in December 2020).”

NGS Unit 1 and Unit 2 electrostatic precipitators were demolished in mid-January 2021.

All three precipitators were original to NGS. They removed 99.5% of fine fly ash from the flue gas before it could be discharged from the stacks.

The plant’s three, 20,000-ton, 245-foot-tall boilers (and support structures) were demolished in early March. The demolition of the boilers was the most complex demolition because of the amount and mass of the steel in the boilers, according to SRP.

“This is why NGS is being demolished right now because it is on Navajo land,” Hardeen added. “It has to be returned in as natural a state as possible.”

Highway 264,

Highway 264, I-40, WB @ Winslow

I-40, WB @ Winslow